Digital Dentures

Digital Dentures

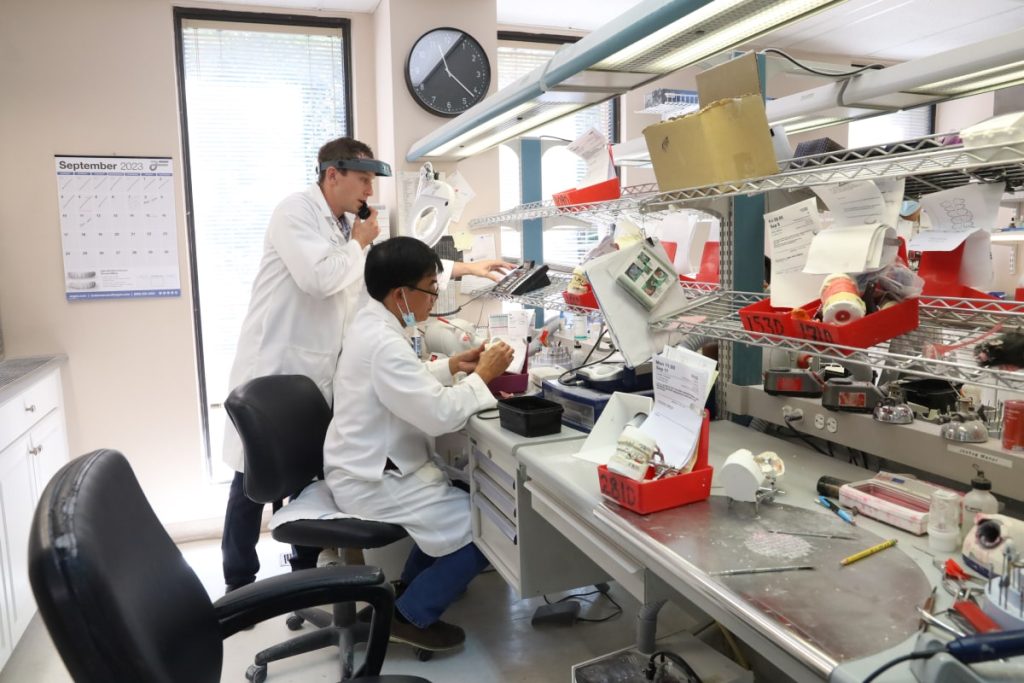

Watersedge Dental Laboratory produces precision digital dentures for dentists throughout Ottawa and North America.

The integration of cutting-edge digital denture production techniques at Watersedge has streamlined and modernized much of our denture fabrication process. Leveraging this advanced dental technology enables us to pass on the benefits of heightened efficiencies to you, ensuring the very best outcome for your patients.

Digital dentures have swiftly become the preferred solution for many, particularly in cases involving partial dentures.

At Watersedge Lab, producing Ottawa dentures of superior quality is paramount. For more complex and full denture cases, we draw upon our decades of traditional denture manufacturing expertise to ensure optimal functionality, aesthetics, and comfort.

"A collective of the most talented and passionate people I have ever known. The atmosphere of teamwork is treasured and comes through in all things we do and present to the world. A special sense of joy and pride is always in the air. "

What Are Digital Dentures?

The word “digital” in digital dentures refers to the process used to capture a detailed scan of a patient’s mouth and the fabrication of the dentures themselves.

The digital denture process starts in-office with the use of a chairside intraoral scanner to obtain highly precise 3D images of a patient’s oral cavity. Next, these digital files are shared with Watersedge Lab and introduced to CAD/CAM (computer-aided design/computer-aided manufacturing) software, where we translate the 3D “impressions” into detailed denture designs. Our full-time CAD/CAM design team then customizes each design to achieve the functional requirements and the best possible fit. The final step involves producing the physical denture using either a 3D printer, a milling machine or a combination of the two.

All dentures, whether part of our digital denture workflow or traditionally produced at Watersedge Dental Lab, are hand-polished in preparation for delivery to the patient.

Digital Dentures vs. Traditional Dentures

Digital dentures mark a significant departure from traditional dentures. The differences span from design and fabrication to the materials used and record-keeping processes.

At Watersedge, we have seamlessly integrated digital dentistry and conventional denture manufacturing into our workflow. Regardless of technique, we prioritize delivering top-quality solutions tailored to each denture case. Recognizing that every situation is unique, we understand there is no one-size-fits-all answer.

If you have questions about the best choice for your patients, please don’t hesitate to contact us. We’re here to provide guidance and support.

Pros & Cons of Digital Dentures

Pros of Digital Dentures

Overall, and especially with respect to partial dentures, digital dentures offer significant advantages over conventional dentures. Some benefits of digital dentures include:

- Minimally invasive impression acquisition

- Fewer appointments and less chair time

- Faster design and manufacturing

- Reduced turnaround time

- Digitized scans and design files

- Expedited replacements

Cons of Digital Dentures

While a purely digital workflow offers many advantages, it’s essential to acknowledge this technology is ever-evolving and inherent limitations persist.

Currently, digital scans for full dentures present challenges. For complete dentures, intraoral scanning cannot precisely capture loaded soft tissue, which limits the achievement of optimal suction—a crucial element for effective full dentures. As such, we prioritize traditional methods for full dentures to ensure the necessary suction needed. Conversely, when creating partial dentures that will be attached to natural teeth, a clean digital scan is more than adequate for denture fabrication.

Another constraint pertains to the materials used. Unlike the acrylics used to produce traditional dentures, current digital options lack the vein-like appearance of natural-looking gums. Lucitone 199, a premium acrylic we often use, sets a high standard for natural aesthetics, which current digital options struggle to match.

Lastly, digital denture production methods introduce potential points of failure due to layering. Both milling and 3D printing require that teeth be glued and bonded into sockets in the base, creating areas of weakness. Our analog technique directly incorporates and cures denture teeth into the acrylic, resulting in a stronger, homogenous structure compared to digital methods.

The Future of Digital Dentures

We eagerly anticipate the evolution of digital dentures. Emerging technologies, such as inflatable tools which adapt to palatal surfaces, showcase the industry’s innovation potential. As digital dental technology matures and becomes more accessible, we envision a future where digital dentures fully align with our commitment to quality and aesthetics.

Request Digital Dentures from Our Ottawa Lab

When requesting digital dentures from Watersedge Dental Laboratory, we require:

- Digital File of Intraoral Scan and/or Impressions

- Prescription

- Consultation (if needed)

Upon receiving your patient’s files and prescription, we will assess any specific requirements and decide on the appropriate course of action. We are always available for a phone consultation if you have any questions; don’t hesitate to contact us.

FAQs

If a patient requires replacement dentures, we can recreate an existing denture (and exactly match the original specifications) with the digital records and designs we retain.

The longevity of digital dentures is based on factors like maintenance, wear, and individual habits. With proper care and regular dental visits, they will last many years.

Yes, the manufacturing process for 3D-printed digital dentures uses biocompatible materials and fully meets the safety standards for oral health.

The cost of digital dentures can vary, but generally, they are slightly higher or comparable in price to conventional dentures.

Partnership and Collaboration With Ottawa Dentists

Watersedge Dental Lab is a trusted leader in digital denture services in Ottawa. We are renowned for cultivating strong working relationships with our dental partners and our commitment to enhancing patient care.

A Trusted Resource for Digital Dentures in Ottawa

Leveraging cutting-edge technologies, expert craftsmanship and a stringent quality control process, Watersedge Dental Lab delivers premium digital dentures in Ottawa.

Contact our team if you have any technical inquiries or require diagnostic guidance. We are ready to address your questions without charge.

Why Choose Watersedge as Your Digital Denture Lab

Watersedge understands the time-sensitivity of your denture needs and the criticality of accurate fabrication. With decades of expertise in digital and traditional denture production, fitting, and maintenance, you can count on us for expert craftsmanship, exceptional customer service, and punctual delivery.

Comprehensive Support and Service

At Watersedge, every step of our procedures is designed with dental practitioners in mind.

Our chief objective is to optimize your valuable time. We’ve assigned four dedicated Quality Assurance associates as your direct liaisons to enhance communication. These team members are easily reachable and prompt in their responses, as they have insight into every case we manage.

Additionally, we’re happy to provide guidance and assist you in meeting the evolving needs of your patients.